Vakuum SRV®5 Tribometer

Friction and Wear Measurement in a Vacuum

The Advantages of the SRV®5 Teamed with Vacuum

- High vacuum of up to 10-6 mbar

- Materials research

- Self-lubricating systems

- Spiral orbit specimen holder set for ASTM F 2661-07

- SRV® standard tests

Areas of Application of the Vacuum SRV®5 Tribometer

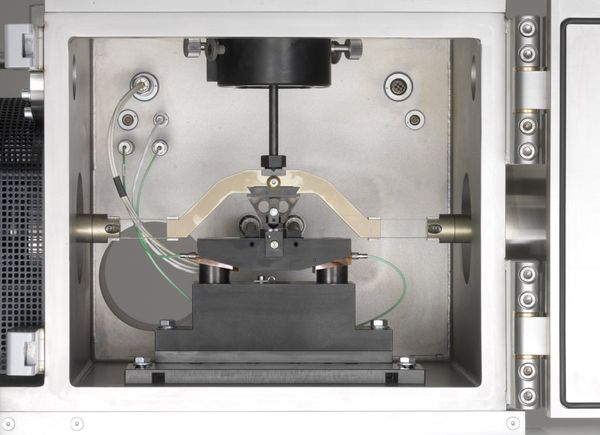

The vacuum SRV®5 tribometer is ideal for studying the friction and wear of solid materials, hard coatings and lubricants under high-vacuum conditions.

Typical applications include self-lubricating coatings, the resistance of sliding coatings, the compression of surface contacts, vacuum pumps or applications in the aerospace industry. A spiral orbit specimen holder set is available for testing the service life of lubricants and materials under vacuum conditions according to ASTM F 2661-07.

The Advantages of the Vacuum-Version SRV®5 Tribometer

A special test chamber is required for measurements under vacuum. All standard specimens as well as your own components can be installed in the chamber which was designed to allow the use of the SRV®5 tribometer's entire range of options. This expands the range of applications for measurements in a vacuum to a significant extent.

A two-stage pumping system is available as an option.