Mobility Keeping track of friction and wear with tribometers for all kinds of applications

Quick and cost-effective development processes, precise specifications and sustainable solution concepts thanks to application-oriented tribometry

Hardly any other industrial sector is targeted as much by politics and the public as the mobility sector. Sustainable and durable means of transport with energy-efficient drive systems have to be brought onto the market in ever decreasing innovation cycles as well as in a cost-effective manner. This is where our application-oriented, versatile and highly precise tribological solution concepts come into play. Taking into account the aspects of wear resistance and energy efficiency, we help our customers and partners specify materials and operating fluids as early as during the design and predevelopment stage. When doing so, we always start with a holistic system analysis and the definition of the demands placed on the component to be specified. Based on that, we cooperate with our customers and partners to develop test methods that are able to differentiate and specify the friction, wear and fatigue behaviour of materials and operating fluids, surface finishes, heat treatments and entire components in a precise, robust and time-saving manner. Take a look at the categories listed below and discover the test methods and solution concepts that we hold ready for you.

Categories

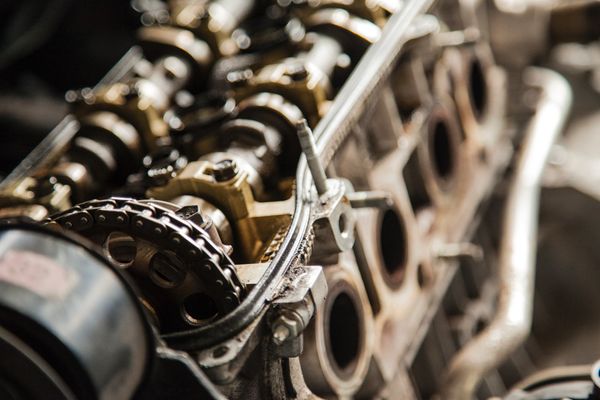

Combustion engines

- Specification of low-viscosity engine and transmission oils with regard to friction and protection against wear (temperature, load and speed-dependent)

- Friction reduction, scuffing resistance and wear protection within the piston ring/cylinder liner system (coatings, selection of materials, honing structures and motor oils)

- Wear resistance of brake pads (reduction of fine particulates)

- Wear resistance and fatigue strength of lightweight materials for functional components

- Increasing the service life of clutch linings by reducing the drive power

- Wear resistance of high temperature components, e.g. in the turbocharger assembly

- Quantitative and qualitative friction and wear assessment for gasoline and

- Specification of e-fuels as the “fuels of the future” taking into account the aspects of wear protection and dynamic material compatibility

Relevant standards and specifications

ISO 19291 / DIN 51834-2 / DIN 51834-4 / DIN 51834-7 / ASTM D6425 / ASTM D7421 / ASTM D8316 / CEC TDG-L-116 / ASTM G181 / MBN 10474 / Q/SY 1495-2012 / ASTM D8227

Ship and Locomotive Drives

- Specification of conditioners in the wheel-to-rail contact area

- Optimisation of sprocket lubricants

- Clarification of dynamic sealing processes and metallic seals

- Tribological optimisation of bearing materials

- Differentiating the functional performance capability of aged operating fluids (functional condition monitoring)

- Tribological optimisation of drive chain systems (e.g. chain drives and tooth flanks)

Relevant standards and specifications

ISO 19291 / DIN 51834-2 / DIN 51834-4 / DIN 51834-7 / ASTM D6425 / ASTM D7421 / ASTM D8316 / CEC TDG-L-116 / ISO 12156 / CEC F-06-A-96 / ASTM D6079 / ASTM D7688/ NLGI HPM-Greases / Mercedes MBN 10474 / Q/SY 1495-2012 / SAE AMS3058

E-Mobility

- Resistance of hairpin coatings to fretting wear

- Dynamic material compatibility of operating fluids within the stator-gear system

- Specifying the scuffing resistance of operating fluids for electric drives

- Quantifying the proneness to noise development of components in electric drive chains

- Wear resistance of materials for components in electric drive chains (e.g. brake pads, gears, bearing shells)

- Abrasive wear of thermal pastes and coolants

- Electric properties of operating fluids subject to dynamic loads

- Durability of component coatings

Relevant standards and specifications

ISO 19291 / DIN 51834-2 / DIN 51834-3 / DIN 51834-4 / ASTM D5706 / ASTM D5707 / ASTM D7594 / ASTM D6425 / ASTM D7421 / ASTM WK71194 / NLGI HPM-Greases

Mobility of the Future, e.g. E-Bikes, Drones

- Increasing the operating range of energy storage systems with friction-optimised components in drive systems

- Durability and service life of lightweight components subject to wear

- Hydrogen compatibility of materials and lubricants subject to dynamic loads

- Wear resistance and energy efficiency by optimising the frictional behaviour of bearing materials

- Specifying the lifetime lubrication of moving parts

- Wear resistance of materials produced using additive manufacturing processes

Relevant standards and specifications

ISO 19291 / DIN 51834-3 / DIN 51834-6 /ASTM D6425 / ASTM D7421 / ASTM D7688 / NLGI HPM-Greases

Interior and Comfort

- Noise caused by stick-slip friction in hydraulic components (e.g. brake systems)

- Durability of surface coatings subject to cyclic loads (e.g. touch panels)

- Reduced wear and failure safety of levers and bolts

- Tribological performance capability of odourless and colour-neutral lubricants in vehicle interiors

- Reliability and free movement of moving parts in steering systems

Relevant standards and specifications

ISO 19291 / DIN 51834-2 / DIN 51834-6 / ASTM D5707 / ASTM D6425 / ASTM D7420 / ASTM D7217 / ASTM D7594 / NLGI HPM-Greases

Tribometers / Equipment Options

- Oscillation standard appliance

- Rotation unit

- Dynamic load unit

- Tilting mechanism

- Fluid pump

- -45°C low temperature unit

- High temperature unit

- Option for measuring the electrical resistance

- Noise emission measurement

- Online wear measurement

- Multi-component block

- Varioblock

- High Resolution Signal Analysis (Software)

- Advanced Tribodata (Software)

- Triboprofiling (Software)

- Fluid pump

- -10°C low temperature unit

- Option for measuring the electrical resistance

- Noise emission measurement

- Online wear measurement

- High Resolution Signal Analysis (Software)

- Liquid bath

- Online wear measurement