Drive Technology The full range of applications covered by tribology

Potentials for optimisation and savings thanks to laboratory-scale tribometry

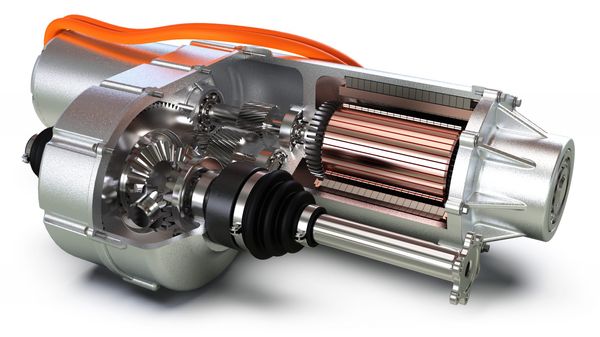

Drive technology deals with the generation of motion by means of power transmission. Be it drive shafts or gear wheels, there are many power units and systems whose frictional behaviour, wear resistance and fatigue strength have a major influence on the entire system's energy efficiency and sustainability. Our solution approaches for the functional tribological testing of lubricants, materials, coatings and components offer potential for optimising systems subject to tribological stresses - and for specifying them for the subsequent production cycle - as early as during the development stage.

Categories

Drive Technology

- Less friction-induced heat generation

- Temperature stability of lubricants

- Optimising the fretting resistance and abrasive wear behaviour

- Lifetime lubrication and dry friction combinations

- Optimised efficiency and reduced energy consumption by improved frictional properties

- Food-safe drive systems and lubricants (optimisation and formulation)

- Selection and optimisation of bearings and bearing materials

Relevant standards and specifications

ISO 19291 / DIN 51834-2 / DIN 51834-3 / DIN 51834-4 / DIN 51834-7 / ASTM D6425 / ASTM D7217 / ASTM D7421 / ASTM D8316 / ASTM WK71194 / Q/SY 1495-2012

Tribometers / Equipment Options

- Oscillation standard appliance

- Rotation unit

- Dynamic load unit

- Tilting mechanism

- Fluid pump

- -45°C low temperature unit

- High temperature unit

- Option for measuring the electrical resistance

- Noise emission measurement

- Online wear measurement

- Multi-component block

- Varioblock

- High Resolution Signal Analysis (Software)

- Advanced Tribodata (Software)

- Triboprofiling (Software)

- Fluid pump

- -10°C low temperature unit

- Option for measuring the electrical resistance

- Noise emission measurement

- Online wear measurement

- High Resolution Signal Analysis (Software)

- Liquid bath

- Online wear measurement