Tribological Hydrogen / Fuel Measuring Cell

H2 tribology - the answer to the challenges posed by green energy

New Tribological Solutions for New Technologies

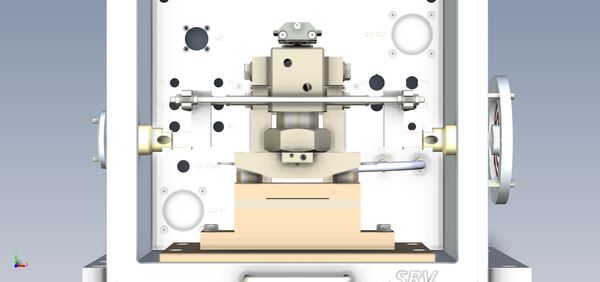

When it comes to alternative energies, hydrogen and e-fuels are considered to be the most promising fuels for our future technologies. A more widespread use entails new questions with regard to the friction and wear behaviour under the respective conditions. Specifically developed for the SRV®-5 tribometer, the hydrogen cell for gas pressures of up to 100 bar is the solution for the tribological challenges resulting therefrom.

The Tribological Challenges Posed by Hydrogen

Bearings, joints, seals and piston rings are among the most heavily stressed components. With the change from air or other gas environments to a hydrogen atmosphere, the behaviour of materials and lubricants changes in terms of wear, fatigue and friction.

It is for this reason that the materials and lubricants intended for hydrogen infrastructures, engines, compressors, etc. must be selected under test scenarios that are as close to reality as possible, thus simulating a hydrogen environment. This makes a decisive contribution to the development and operation of durable, fail-safe and energy-efficient plants and systems.

- Suitable for hydrogen, fuel and other gases

- Pressures of up to 100 bar

- The Pressure Vessels Safety Regulations are not applicable

- -40°C to +150°C

- Various specimen geometries

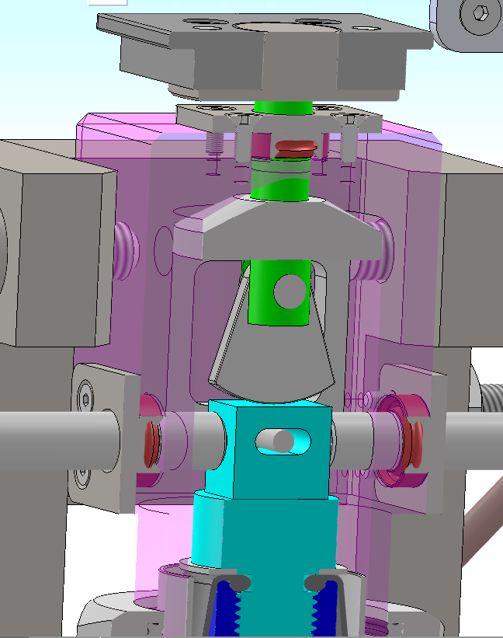

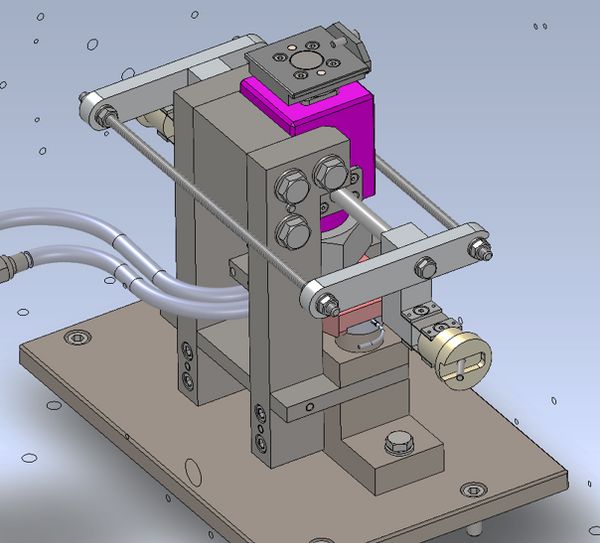

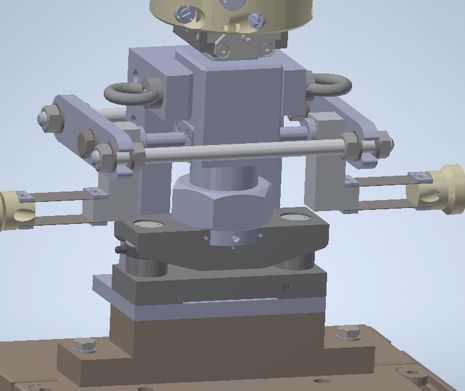

Measuring Principle

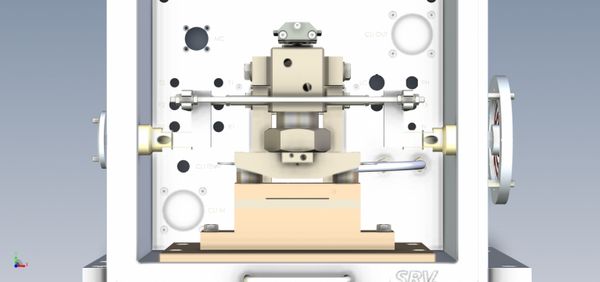

Developed in cooperation with research partners, the tribological hydrogen cell is intended for translational friction and wear tests. The cell can optionally be integrated into existing SRV®5 tribometers. Hydrogen, fuel and other gases can be introduced into the cell at pressures of up to 100 bar. With a total of approx. 160 ml, the pressure volume has been calculated in such a way that tests can be carried out at 100 bar without taking into account the Pressure Vessels Safety Regulation. The tribological hydrogen/fuel measuring cell includes gas supply regulation and fundamental safety monitoring features. The cell has been designed for tribological model testing within a temperature range from -40°C to +150°C (requires an external temperature control for low temperatures).

The specimen geometries that can be used are spheres in a diameter of 10 mm (point contact), cylindrical rollers (line contact) and surface contacts (ring surface), all of which are inserted against a plate as the lower specimen. Stroke, standard force and frequency are within the parameter ranges which must be adhered to according to the relevant lubricant and material testing standards applicable to the SRV® tribometer.