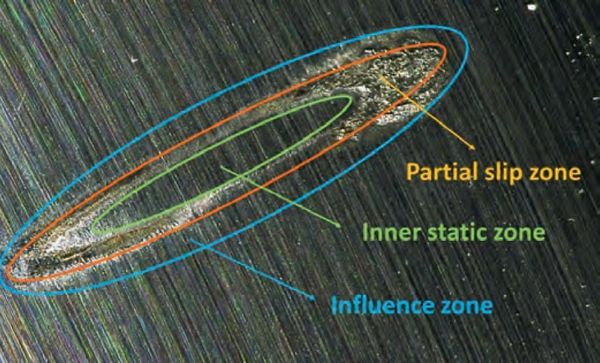

Rolling bearings that are often only operated at small swivel angles or that are exposed to vibrations when stationary can show typical damage after only a short period of operation.

This can be classic false brinelling damage, so-called stand-still marks or fretting damage. Damage resulting from these phenomena can significantly reduce the fatigue life of bearings and cause wear-related increases in frictional torque that endanger the function of units. Since this is a special wear problem, the failures do not correlate with standard calculation approaches for life estimation such as ISO 281, since these are based on fatigue theories.

It is therefore imperative to have application-oriented and meaningful laboratory tests available to check and evaluate the suitability of lubricants or rolling bearing modifications.

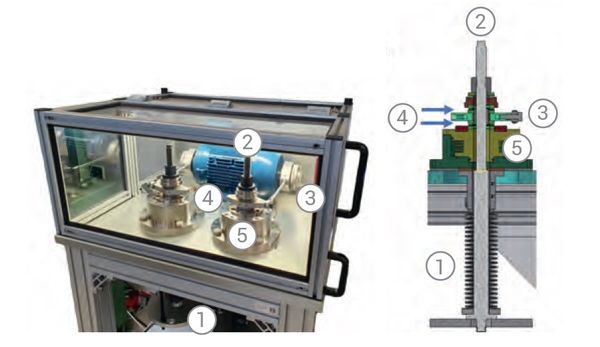

- Axial load application by means of disc springs

- Pull rod

- Movement initiation through eccentric and connection rod

- Upper and lower test bearing

- Temperature control

The best-known standard test for this application is the socalled SNR-FEB2 test, which is frequently required, for example, for greases in the pitch bearings of wind turbines (normal force 8 kN, swivel angle ± 3°). KTM has also developed a laboratory standard test that can be used to simulate bearings that are only subjected to very small swiveling movements or even vibrations (swiveling angle ± 0.5°).

| TEST RIG PARAMETERS | |

|---|---|

| Axial force | 100 N up to max. 9 kN with spring assembly |

| Test duration | Variable programmable (SNR-FEB2 test 50 h) |

| Swing angle | ± 0.1° to + 3° by eccentric |

| Swing frequency | 5 to 25 Hz |

| Tempering | Active temperature control with a heating and cooling jacket on the test head optional (-20°C to 80°C) |

| Lubrication | Grease lubrication / oil lubrication optional |

| Measurement | Weighing before and after the test, bearing temperatures, axial force (optional), motor current (torque) optional |

| Test bearing | Axial deep groove ball bearing Type 51206; outside diameter 41 mm; horizontal mounting position |

| Test conditions | Endurance run with constant parameters |

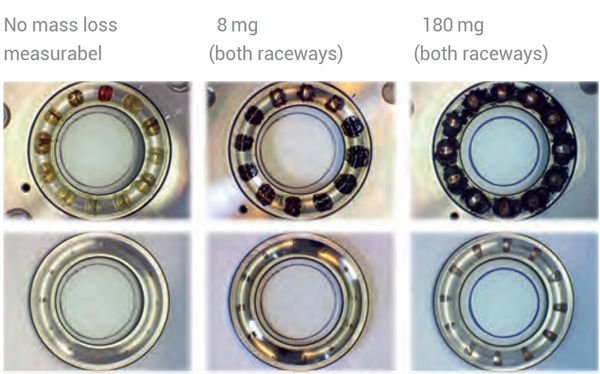

EXEMPLARIC MASS LOSSES IN THE SNR-FEB2 TEST

Literatur

Französische Norm NFT 60-199 (Normalisation Francaise). Nft 60-199 – aptitude à résister au faux effet brinell, 1995.

M. Grebe: False-Brinelling und Stillstandsmarkierungen bei Wälzlagern – Schäden bei Vibrationsbelastung oder kleinen Schwenkwinkeln. Narr Francke Attempto Verlag, ISBN: 9783825251604; DOI: 10.36198/9783838551609. 2017

R. de la Presilla; S. Wandel; M. Stammler; M. Grebe; G. Poll; S. Glavatskih: Oscillating Rolling Element Bearing Tribology: a Review of Testing and Analysis Approaches; Tribology International, Elsevier; https://doi.org/10.1016/j.triboint.2023.108805; 2023.

M. Grebe, A. Widmann: Comparison of different standard test methods for evaluating greases for rolling bearings under vibration load or at small oscillation angles; Lubricants 2023, 11(7), 311; https://doi.org/10.3390/lubricants11070311. (peer reviewed)

Y. Sosa: False brinelling: An increasing type of a rolling bearing wear Industry experts discuss how to identify false brinelling, prevention scenarios and lubricating strategies. Tribol. Lubr. Technol. 2023, 79, 60–68.

M. Grebe, J. Molter, F. Schwack, and G. Poll: Damage mechanisms in pivoting rolling bearings and their differentiation and simulation. Bearing World Journal, 3:72–85, 2018

C. Schadow.: Stillstehende Fettgeschmierte Wälzlager Unter Dynamischer Beanspruchung. Ph.D. Thesis, Otto-von-Guericke-Universität: Magdeburg, Germany, 2016.

M. Stammler: Endurance test strategies for pitch bearings of wind turbines. PhD thesis, Stuttgart: Fraunhofer Verlag, 2020.

S. Tetora; C. Schadow; D. Bartel: Influence of Grease Properties on False Brinelling Damage of Rolling Bearings. Lubricants 2023, 11, 279. https://doi.org/10.3390/lubricants11070279