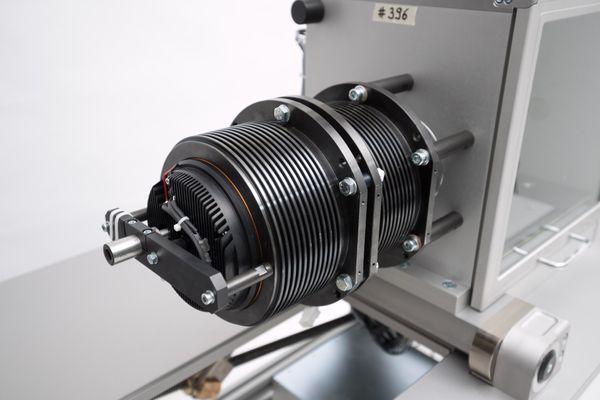

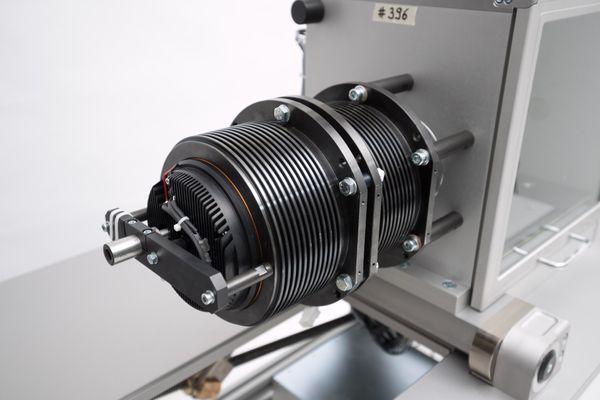

SRV®5 Tribometer -

Our All-Rounder

The original SRV® - a practice-oriented and internationally appreciated model of success in friction and wear test.

SRV - friction wear testing our synonym with Tribology

Our All-Rounder, the SRV® test tribometer stands for decades of experience, worldwide use, maximum precision, reproducible results and a high degree of versatility. Featuring a patented test principle, the SRV®5 tribometer allows for high-precision friction and wear tests of lubricants, materials, coatings and components. The SRV®5 tribometer offers a wide range of practice-relevant test concepts, even in its standard configuration with oscillation. By the way: "SRV" is a registered trademark of Optimol Instruments Prüftechnik GmbH and stands for "Schwingung Reibung Verschleiß" (oscillation, friction, wear).

- The patented original SRV®

- The basis for all SRV® standard tests according to DIN, ASTM and ISO

- Numerous application-specific tests can be implemented

- More than 30 standard holders and adapters

- Customized solutions including the development of complete test scenarios

- The basic structure of the SRV®5 serves as a technology platform for further applications and options

- More than 50 years of development and manufacturing expertise

- SRV test made in Germany

- Specialized for fretting tests under dry and lubricated conditions

Would you like a personal consultation?

Then book an appointment with our experts directly here:

Dr. Ameneh Schneider

Developed by Users

The SRV® tribometer was invented more than 50 years ago by the then-developers of Optimol Ölwerke. Intended as an innovative type of friction and wear screener for the development of lubricants, it quickly became known around the world throughout the entire industry.

The requirement was to develop a test methodology that would quickly deliver differentiable and reproducible friction and wear results. Oscillation was chosen as the test motion, which, in combination with the test force, ensures the most realistic and practical stress conditions possible – at that time, one of the first fretting tests worldwide. The SRV (oscillation, friction and wear) tribometer was born. The fundamental tribometrical principle for representing the friction value, which is still valid today, is the study on the cyclic transition from static to dynamic friction. Permanent further development and continuity have made the SRV® tribometer the worldwide standard for tribological model testing.

Measuring Principle

In its basic version, the SRV®5 tribometer works with oscillating movements. A periodic, sinusoidal translational motion within a frequency range from 0.001 Hz to 500 Hz and with strokes from 0.01 mm to 5 mm is generated by the electromagnetic linear drive as the relative movement of the test contact. The determination of a material combination's coefficient of friction, with or without intermediate medium, is true to definition:

- Frequency, stroke, test force, test temperature and test duration are predetermined test variables.

- The counter-body is pressed onto a base body with a defined normal force.

- The counter-body oscillates on the surface of the base body in a sinusoidal motion pattern.

- The lateral friction force resulting from the movement of the counter-body on the base body is measured.

- The coefficient of friction is calculated and recorded online throughout the entire test period.

- Optionally, the total amount of wear can be measured and recorded both during and after the test.

Technical Data - Standard Configuration

Using the SRV®5 tribometer with oscillation module, you can carry out a wide range of simulations, measurement and test projects and tribological tribological friction and wear analyses.

- Surface pressures within a range from 0.01 to > 6500 MPa

- Sliding speeds from 0.0001 m/s to 0.5 m/s in the test contact

- The oscillation drive's acceleration of 20 g proves the performance capability

- Operating temperatures of the friction contact from room temperature to 350°C (further temperature ranges available as an option)

Options

- 1-100 Newton

- 2-200 Newton

- 20-2000 Newton

- 25-2500 Newton

- 50-5000 Newton

- Dynamic load

- Low temperature: from -45°C to R

- High temperature: from RT to 1000°C

- Manual gas injection

- Air conditioning at 20-40°C and 30-90% relative humidity

- H2 / hydrogen cell (for oscillation)

- Vacuum at 10⁷ mbar (see special applications)

Vacuum-SRV® - High temperature / pressure of 10 bar / 700°C (see special applications) SRV® X-AT

- Rotary drive with rotational speeds* of up to 3000 rpm

- Combined drive: The rotary and oscillation drives and their measuring sensors can also be combined, which creates a vast range of possibilities for simulating practice-oriented 4D motion patterns

- Reversing movement

- Movement perpendicular to the measuring direction (Y-axis)

* The rotation feature creates further test scenarios:

- Pin - disc

- Disc - disc

- Ring - disc

- Axial bearing

- Cooling lubricant module

- Four-ball test

- ... and many more

- Standard specimen according to DIN 51834

- Special application-specific specimens

- Holders for different specimen geometries

- Component holders

- Manufacture of customised holders

- Measurement of the total amount of wear

- Nanoscale wear measurement with radionuclide technology (see special applications) n-RAI

- Electrical resistance

- Acoustic emission

- Temperature near the friction point

- Temperature and humidity in the test chamber

- Infinitely variable inclination (0 - 90°)

- Fully automatic specimen fitting A-POS

- Automatic test force calibration

- Oil supply (circulating, microlitre pumps, drip and immersion lubrication, oil baths)

- Varioblock

- Multi-component block

- Calibration mechanism for calibrating the friction force

(see special applications) Software solutions

Watch our video tutorial and discover how easy it is to start a SRV® fretting test.