ETS Easy Tribology Screener: the smart desktop tribometer

The easy way to measure friction and wear

ETS - Tribology Made Easy

The ETS (Easy Tribology Screener) has everything that characterises a proper and smart desktop tribometer. Featuring compact dimensions and equipped with intuitive software, it is ready for use, fully equipped and user-friendly. The ideal entry-level device for tribological investigations, the ETS is an all-rounder for measuring friction, wear and fretting wear resistance of coatings, materials, lubricants, additives and much more. Unique in its class, it indicates the linear wear immediately during the measurement. This makes subsequent, time-consuming microscopic evaluations obsolete and provides actual values.

Research, Development, Continuous Quality Control.

The ETS delivers precise and repeatable friction wear results in a quick and straightforward manner. Designed as a desktop tribometer, it fits into the daily laboratory routine. Be it for product development purposes or continuous quality control. The ETS delivers reliable "actual results" on friction coefficients and material wear. Whether it comes to pre-screening or monitoring the condition of lubricants. As regards oils, it is possible to quickly combine extensive chemical and physical analyses of continuous condition monitoring processes into one measurement. This saves both time and costs.

- Quick commissioning

- User-friendly operation

- Intuitive software

- Pre-installed test programmes

- Online wear measurement

- Perfect fit for fretting tests

- Inexpensive consumables

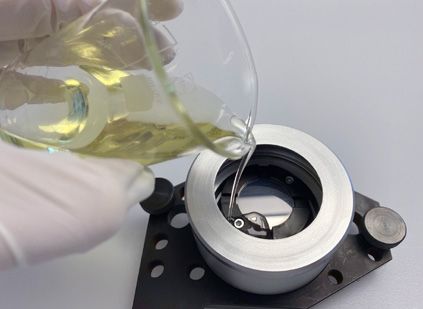

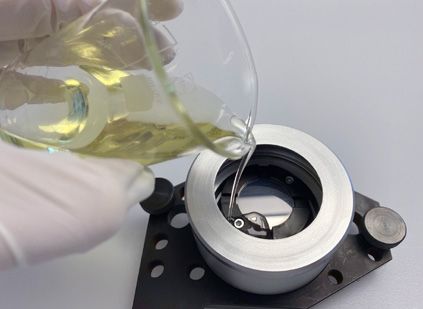

Measuring Principle – friction wear test

The ETS (Easy Tribology Screener) is equipped with an electromagnetic linear drive that generates a periodic, sinusoidal translational motion within a frequency range from 10 Hz to 70 Hz and with strokes from 0.01 mm to 3 mm (oscillation) as the relative movement of the test contact. The lower oscillating specimen is mounted on a reciprocating table, while the upper specimen is immobile. During the test, the coefficient of friction and the linear wear are displayed and recorded in real-time. Our specimens are available in different materials. In addition to the standard discs (lower specimen), it is also possible to attach your own material samples. Upper specimens are available as point, line or area contacts.

Technical Data

Test force: 1 - 300 N

Resolution: 100 mN

Stroke: 0.01 - 3.00 mm

Frequency: 10 - 70 Hz

Temperature: RT - 200° C

Resolution: 0.1 K

Controller accuracy: 1 K

Test duration: 1 min - 72 h (optionally extendable)

Scope of Delivery

- ETS desktop unit for operation, control and evaluation

- Industrial PC with touch screen

- Real-time wear measurement

- Set of standard specimens

- Point-contact specimen holder for spheres in the following diameters: 4mm, 6 mm and 10 mm

- Line-contact specimen holder for cylindrical rollers in the following diameters: D 6 mm x L 8 mm

- Oil bath (centred)

- Reference oil

Application notes

Watch our product video to learn more about the ETS's advantages for friction wear tests.