n-RAI - Nanoscale Wear Measurements

Trace analysis in tribology

The n-RAI - Added Value for Research and Development

Based on radionuclide measurement technology, the n-RAI is used for measuring nanoscale wear with high precision and efficiency by counting the number of radioactive particles. An additional option to complement our tribometers, it is a cost-effective, user-friendly analysis and measurement method offering a good practical correlation as well as accurate, conclusive results within short test times. Using the n-RAI, it is possible to expand the SRV® measurement spectrum for both standard tests and special tribological issues in model testing:

- Practice-oriented measurement scenarios for the development of engines and lubricants

- Determination of the difference between wear during the running-in phase and constant wear

- Differentiation between the wear of any given pair of friction partners, e.g. piston ring and cylinder wall

- Emergency running properties of engine components

- Effects of the fuel composition on the wear behaviour of assemblies/components in motor vehicles (e.g. piston ring/working surface of the cylinder)

- Wear behaviour of different metal alloys with a reference lubricant

- Effect of different additives and additive concentrations in known base oils on the wear behaviour

- Lubricant, additive and fuel optimisation

- ERP analyses of lubricating oils

- Ageing test and service life estimation based on the wear rate/failure conditions of lubricating oils

- Creation of a tribology system's complete tribological profile

- Maximum sensitivity

- Cost-effective

- User-friendly

- Competent advice and support

- Short test times compared to engine test rigs

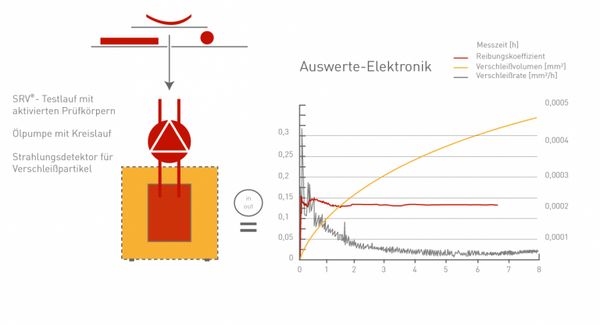

The n-RAI's Measuring Principle

The specially developed radionuclide-based wear measurement technique marks the specimens to be examined by means of thin-layer activation. Our n-RAI's advantage lies in the sensitivity of our measurement technique, which allows for the lowest possible activation rates.

For the licence-free handling of radioactive substances and the avoidance of an unnecessarily high level of activation, the n-Rai works with activity concentrations between 5% and 30% of the permissible limit. That is so low that we have to shield our measurement technology from external natural radiation. Measurements can therefore be carried out in any laboratory environment without taking any further measures.

How Testing is Performed

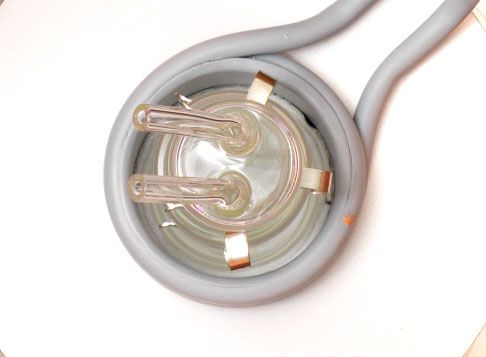

- Samples with activated zones are tribologically loaded in the SRV®5 tribometer or 2dsik.

- A pump transports the wear particles to the radiation detector via the lubricant circuit.

- The measurement of ionising radiation makes it possible to correlate the radioisotopes counted with the total number of wear particles.

- Based on the known activity and isotope distribution, the wear in nm/h is determined from the measurement data of the detector and displayed online.

- Usually, it only takes a few minutes to measure and detect a few nanometres of wear. The longer the measurement and test time selected, the lower the wear rates that can be distinguished.

- It goes without saying that our tribological testing institute can carry out n-RAI-based wear measurements for you. Get in touch with us to receive competent advice.

The n-RAI allows for the implementation of a wide range of new measurement options

As for lubricants:

- Wear protection and adhesion properties

- Lubricity under varying loads (temperature cycles, varying sliding speeds, load cycles)

- Investigation of the effects of biological or mineral fuel components in engine lubricants

- Investigation of the influence of different oil ageing conditions on the wear process

As for materials:

- Reduction of friction losses by optimising the surfaces and shapes of the friction partners in the tribological system (e.g. piston ring/working surface of the cylinder)

- Exact wear quantification on the base or counter-body during the test run

- Investigation of the effects of biological or mineral fuel components in engine lubricants

- Effects of surface treatments (e.g. hard coatings, honing, laser texturing)

As for the system:

- Resolution capacity up to a wear depth of 10 nm, depending on the surface condition and activity distribution

- Investigation of the system behaviour under special load conditions, e.g. in the area of the top dead centre

- Interactions between lubricant and material (surface)

- Simultaneous recording of the wear and all previous SRV® measurements

As for specimens:

- Material-specific activity and isotope distribution: The radioactive isotopes' spatial and quantitative distribution is determined and verified for each alloy system.

- Zonal activation: The sample is deliberately activated only in those places where this is necessary for measurement.

- Activation of an ultra-thin surface layer: Only an extremely thin surface layer of the sample is activated by particle bombardment. This results in clearly defined, extremely small volume doping.