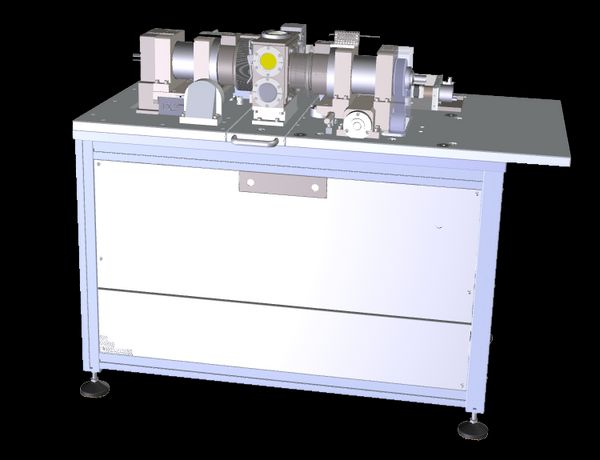

Tribological Model Test Equipment & Test Benches.

We offer mechanical friction and wear test benches, tribometers, component tests, accessories, options and much more from a single source.

Test benches

and tribometers

With our range of tribological model testing equipment and test benches, we reliably support you in your responsible development work:

Save money in the product development cycle by subjecting your products to realistic, laboratory-scale functional testing. Suitable test methods save both time and money, as you will be able to determine your product's tribological performance as early as at the pre-development stage.

For decades, our customers have relied on our practice-oriented and internationally renowned model of success, the SRV® test system. Subjected to continuous development, our tribology solutions always incorporate the latest findings and test results.

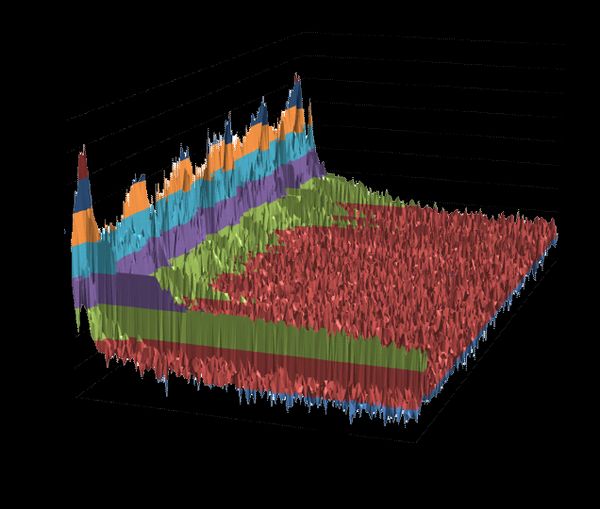

To achieve precise results, functional tribological tests require realistic environmental conditions and maximum accuracy. We solve these requirements with special designs based on our tried and tested models. Thus, it is no longer a problem to carry out nanoscale wear measurements, measurements under vacuum or pressure, and measurements in special atmospheres.

Special

Applications

Functional testing with our robust industry standard for friction and wear tests under vacuum with up to 10⁷ mbar and optional high temperature

Tribological Hydrogen / Fuel Measuring Cell

For testing the friction and wear properties of lubricants and materials in model systems at pressures of up to 100 bar

The pressurised high-temperature superheated steam SRV® version for tribology testing with model geometries in extreme applications, e.g. in gas atmospheres, with steam or with high-temperature gases.

The perfect addition to our range of tribological systems

Online wear measurement at nanometre level using radionuclide measurement technology as an in-line detector, for any test benches and tribometers

Test bench for heavily stressed rolling contacts under vacuum at up to 10³ mbar with additional measuring options and control possibilities

Options and

Accessories

Operator, control and evaluation software from a single source. Intuitive software solutions for efficient and intuitive tribometry

Services

We provide our customers with a full-service package for all areas related to tribometry

For recording more in-depth tribological parameters, such as acoustic emissions or electrical resistances, as well as for setting real operating conditions

Accessories and Spare Parts

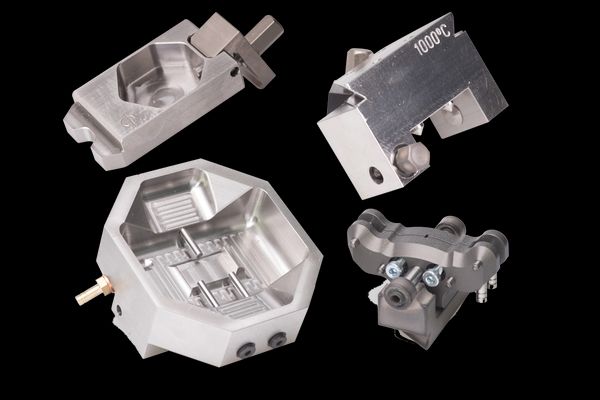

Matching tools, screws, leaf springs, clamping parts or entire appliance parts … You will find the ideal solution in our range of spare parts and accessories (Registration required)

Specimens and Consumables

We have a wide range of reference specimens in stock. Indicated for our test benches and tribometers, they are made of different materials and available in many geometries

For our test benches and tribometers, for both standard geometries and customer-specific requirements including manufacturer know-how

An expert in the field of application-oriented, laboratory-scale tribological testing, we offer our customers more than first-class tribometers and test benches. Worldwide service work, trial orders in our TriboProfiling laboratory and a range of options, accessories and consumables leave hardly any wishes unfulfilled. Get in touch with us and receive competent advice.